Isicelo (Vula okanye sivaliwe isihambisi)

● Ukuphakama kokuphakama

● Izithuba phakathi kweepali

● Ilahleko yokukhanya (Ngenxa yokuhla kwexabiso le-lumen yesibane, uthuli & nobumdaka)

● Ukusetyenziswa kwamandla

Xa uyilo lokuhambisa izibane lucwangcisiwe, eyona ndlela ilungileyo kukusebenzisa izibane zokukhanya phakathi kwe-10 kunye ne-14 leemitha ukuqelelana, zixhonywe kwi-2.4m ngaphezu kwendlela yokuhamba.Nangona izilungiso ezilungele injongo yokuhambisa zinokuvumela isithuba seepali esibanzi ngakumbi, eyona ndlela ilungileyo kukubeka iipali kufutshane kancinane kunowona mkhulu ukuze kubuyekezwe naluphi na utshintsho olunokuthi lwenzeke ngexesha lofakelo.Umphakamo onyukayo oyi-2.4m ngokuqhelekileyo usetyenziswa kufakelo lwemigodi yaseMzantsi Afrika njengoko uvumela ukugcinwa kube lula ngaphandle kwemfuneko yeemvume zokuSebenza kuMphakamo'.Uyilo olunjalo luqinisekisa ukuba imilinganiselo eyamkelekileyo eqhelekileyo ye-avareji ye-50 lux kunye nobuncinci be-20 lux phakathi kweepali iyafezekiswa.

Imimiselo yokukhanyisa kwindlela yokuphuma ifuna i-0.3 lux kumgca osembindini wendlela yokuphuma.Ukuthobela oku, kucetyiswa ngokubanzi ukuba zonke izibane ezitshintshanayo zodidi olungxamisekileyo olubandakanya ibhetri kunye ne-inverter.Esi sithuba sisenokwahluka ngokwenyani ukusuka kumenzi ukuya kumenzi ngokuxhomekeke kunikezelo lokukhanya kunye nepesenti yemveliso phantsi kweemeko zonxunguphalo.

Ukuqinisekisa ukukhutshwa ngokukhuselekileyo kwabasebenzi ngexesha lokumka kombane, kucetyiswa ukuba ixesha lokukhanya okungxamisekileyo yimizuzu engama-60 ubuncinci.

Imiba yogcino olusetyenziselwe izilungiso kuyilo lokukhanyisa inokutshintsha ngokuxhomekeke kwisixhobo abasiphathayo abahambisi, imo engqongileyo apho isihambisi sihambisi sikhoyo, kwakunye nokuba isidluliseli luhlobo oluvulekileyo okanye oluvaliweyo.Kubalulekile nangona kunjalo ukusebenzisa into yokugcina ehambelana neemeko ezilindelekileyo zokusingqongileyo.Ngokomzekelo, xa usenza idizayini yokukhanyisa i-coal bearing conveyor, kufuneka kusetyenziswe into yokugcina into engekho ngaphantsi kwe-0.75, ebonisa ukuba uyilo luqwalasela ukulahleka kwe-25% ekukhanyeni ngenxa yokwakhiwa kokungcola kunye nothuli.

Njengeenkokeli kushishino lokukhanyisa, i-P&Q iyayiqonda imingeni ethile ekukhanyiseni ngokuchanekileyo abahambisi.Siyile ngempumelelo kwaye sanikezela ngezisombululo zokukhanyisa ezininzi kwezona zindlu zemigodi zibalaseleyo kwihlabathi.Sisebenza nemisebenzi yezimayini kwihlabathi liphela kwaye siyazingca ngezisombululo zethu zokukhanyisa ezilungele injongo kunye namava ethu njengeenkokeli kwicandelo lezemigodi kunye neloshishino lokukhanyisa.

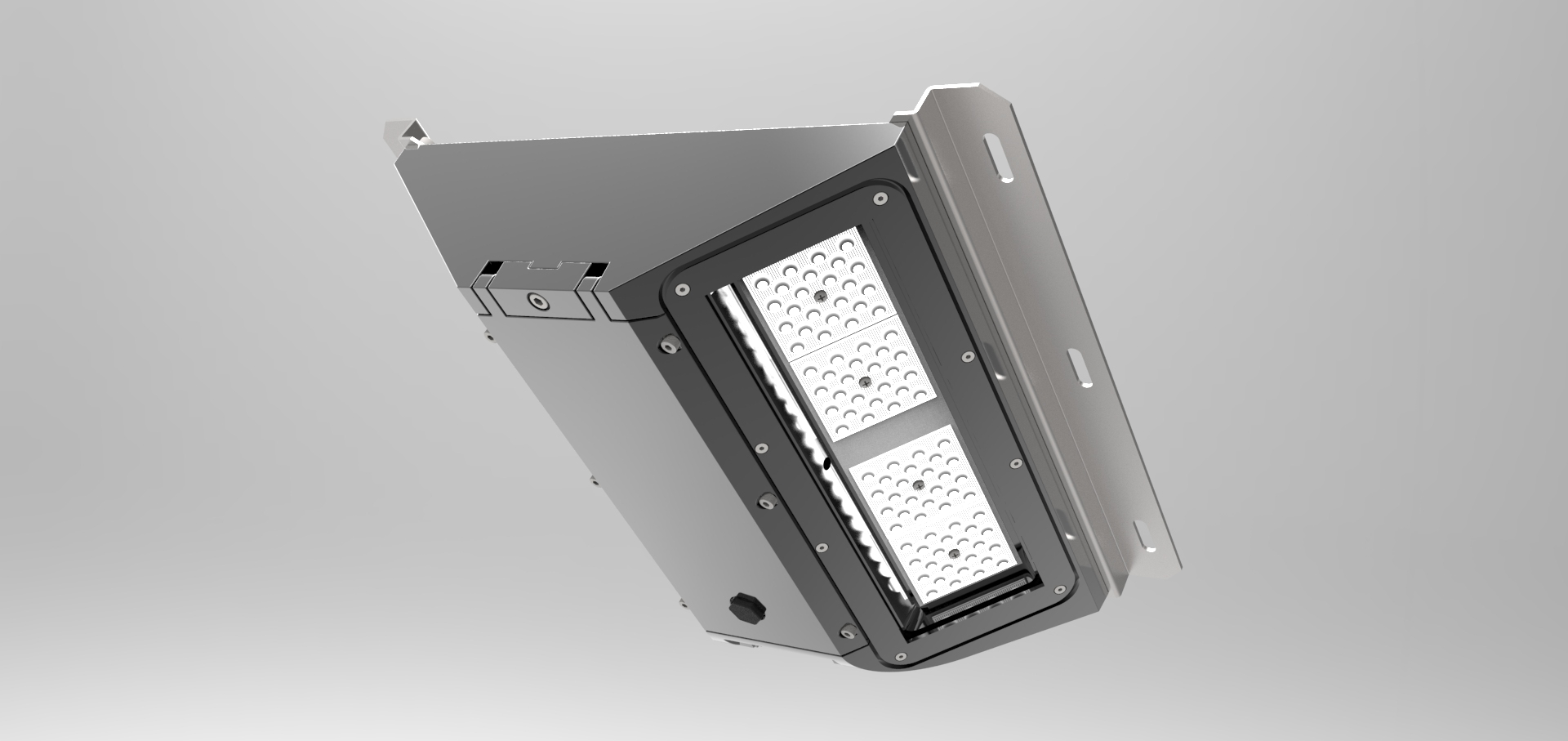

I-P&Q ibonelela ngobuninzi bezisombululo zokukhanyisa zokuhambisa ezibandakanya i-Die Cast AluminiumUmphathi weConveyorkwayeI-Tunnel Master.Zonke izixhobo zokukhanyisa ze-P&Q ziyilelwe ngokukodwa ukuba zilungele-injongo-njongo, zigcineke ngokulula, kwaye zifumaneke ngokusasazwa kokukhanya okwahlukeneyo ukuze zihambelane nayo nayiphi na imigodi okanye ukusetyenziswa kwemizi-mveliso.

Sitsalele umnxeba on +86 18855976696okanye nge-imeyileinfo@pnqlighting.comkwaye ube nomnye weenjineli zethu akuncede ngesicelo sakho sokuhambisa.

Ixesha lokuposa: Aug-14-2023